“never plug extension cords into extension cords” is probably the most common piece of electrical related advice I’ve ever heard. But if you have, say, 2 x 2m long extension cords, and you plug one into the other, why is that considered a lot more unsafe than just using a single 4 or 5 meter cord?

Does it just boil down to that extra connection creating another opportunity for the prongs to slip out and cause a spark or short circuit? Or is there something else happening there?

For that matter - why aren’t super long extension cords (50 or more meters) considered unsafe? Does that also just come down to a matter of only having 2 connections versus 4 or more on a daisy chained cord?

Followup stupid question: is whatever causes piggybacked extension cords to be considered unsafe actually that dangerous, or is it the sort of thing that gets parroted around and misconstrued/blown out of proportion? On a scale from “smoking 20 packs of cigarettes a day” to “stubbing your toe on a really heavy piece of furniture”, how dangerous would you subjectively rate daisy chaining extension cords, assuming it was only 1 hop (2 extension cords, no more), and was kept under 5 or 10 metres?

I’m sure there’s probably somebody bashing their head against a wall at these questions, but I’m not trying to be ignorant, I’m just curious. Thank you for tolerating my stupid questions

Connectors come loose, which makes them dangerous.

They are uninsulated points that allow water and material ingress, and can partially or fully pull apart, causing arching. Which can cause combustion.

This is the main reason these are dangerous, which the majority of this entire thread misses. The added length or connector resistance is somewhat negligible here unless you’re daisy chaining long conductors, which often isn’t the case for in-home extensions.

On a scale from “smoking 20 packs of cigarettes a day” to “stubbing your toe on a really heavy piece of furniture”, how dangerous would you subjectively rate daisy chaining extension cords

As dangerous as one extension cord of their combined length. Don’t forget to verify that every cord rating is above load rating. I recommend to use at least same rating as circuit breaker or get extension cord with circuit breaker built in and never decrease rating down the line without circuit breaker before it, so even if you somehow overload it, there will be protection from it.

AND NEVER COIL OR THERMALY INSULATE! Cords rely on convection for heat dissipation, and spooling and insulating reduces it, thus increasing insulation temperature until it melts and spontaneously combusts. This applies to extension cords in general.

Because this is the Internet, I’ll be pedantic and say the interface where each cord plugs into the next probably adds some resistance as well.

So, 50 cords 1 ft each plugged into each other would have a higher resistance than the same wire at a single 50ft length.

I doubt it really matters in the practical terms of your answer and the question being asked though.

*insert technically correct*

Others have pretty much mentioned it. Too thin of conductors for the total length required which can overload the cable and heat it up. If you’re just charging your phone it’s unlikely to cause a problem but the more amps you pull the riskier it gets.

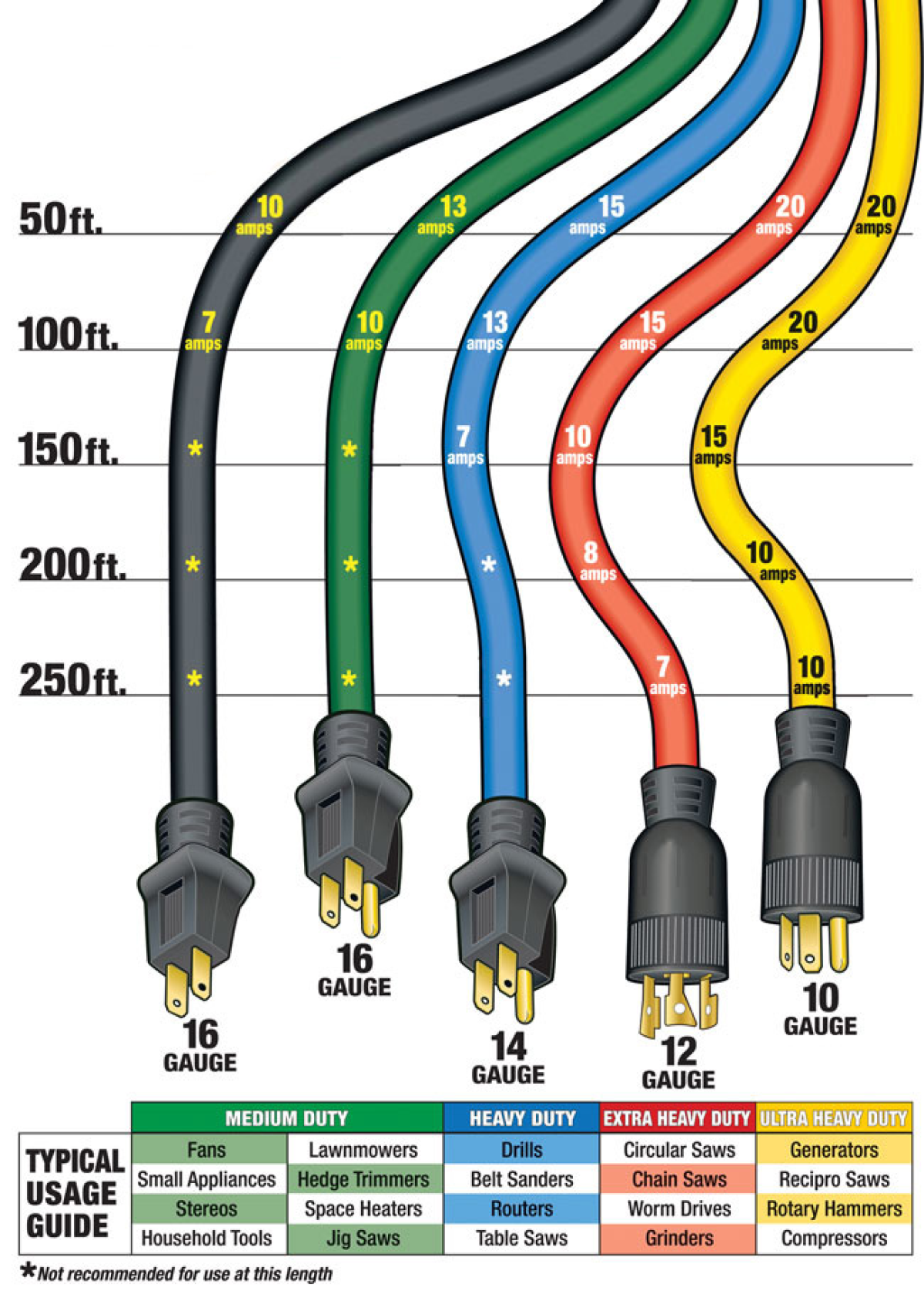

Here’s a helpful chart…

a 50ft 12 gauge extension cord is about $40

$40USD would be $58CAD.

A 50-ft 12-gauge extension cord costs $112+ CAD anywhere in Canada. A 100-ft is $200+ CAD. Like… fffffuuuuuck.

Is it just me or is anyone else perturbed that the cable sizes in this infographic are all the same gauge?

the cable sizes in this infographic are all the same gauge?

They’re not. They are clearly marked as different gauges, except the left most two which have different plug types… one is two prong, the other is three prong.

Space heater is “medium duty” while a router is “heavy duty”?

This is also known as a router

Oohkay.

It’s for putting holes in things. Creating routes? I dunno.

Exactly, can be used to round off corners and all manor of nifty woodworking. Keep hands away from the spinny bit.

router as in ‘tool for finer details in woodworking.’ most router motors can spin at 10000rpm at their lowest and anything with a motor, by definition, uses more power than something without a motor

It doesn’t make sense. Temperature difference does not depends on length.

Adding length creates more resistance which creates more heat. Thinner conductors can’t handle it as well.

And more surface area for heat dissipation. https://lemm.ee/comment/17115060

TIL. Maybe I was conflating daisy-chaining power strips with extension cords and came up with that as a reason it was bad with the cords.

lol “gauge”

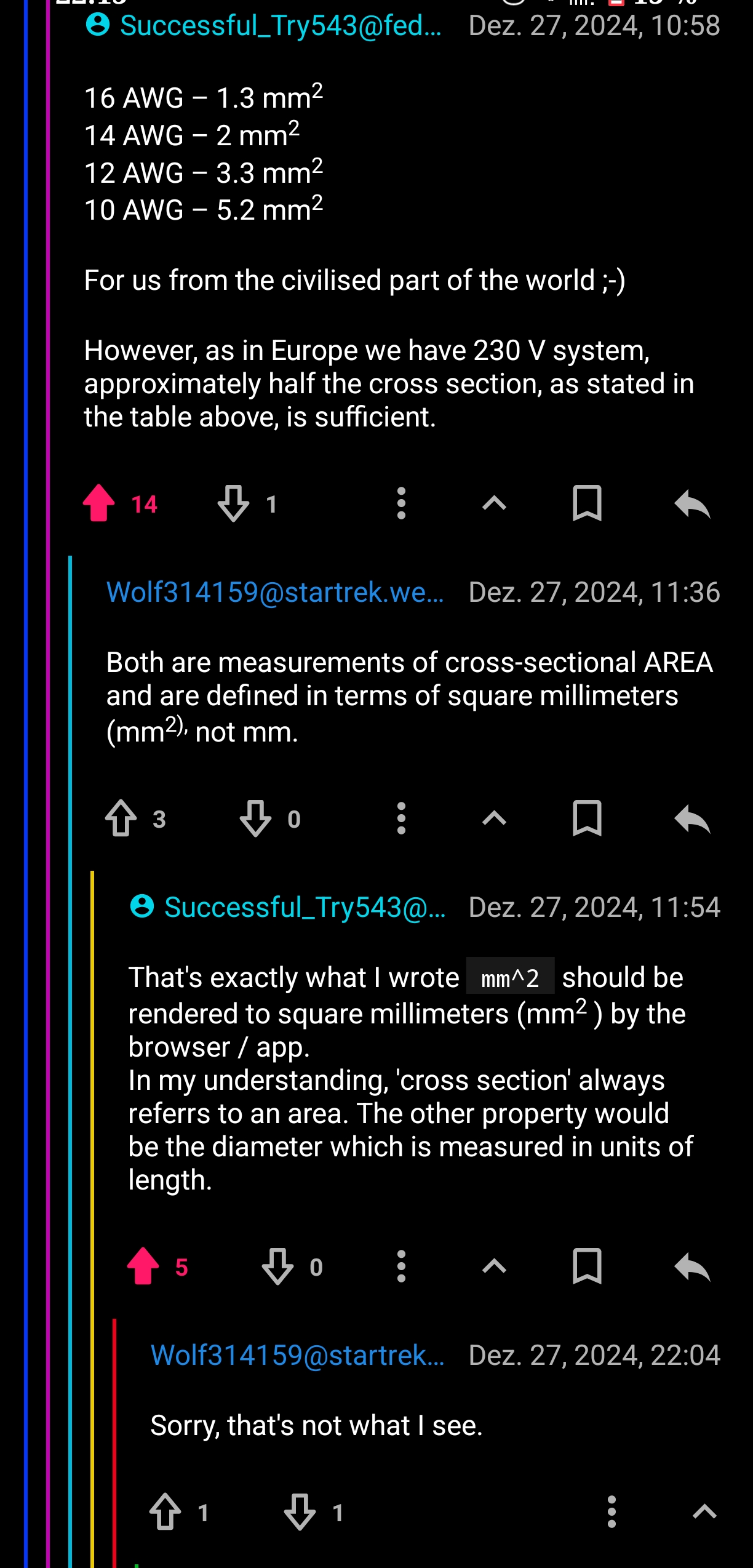

americans will use anything except the metric system

What is the metric unit for cables?

for cross-sectional area? mm2.

I’ve always found gauge to be especially odd, because the number gets smaller as you go bigger, so at one point you can’t go any further even though you can go fatter.

Oh ffs I should’ve known.

Yup, I work with 4/0 (0000) cable pretty regularly, for things like generators or powering large systems. We have a few trunks full of cable, and it takes a crew of 2 or 3 to actually lay it because it’s so heavy. Usually one person pushing the trunk along, one focuses on uncoiling it from the trunk, and one focuses on actually laying the cable. We use five conductors at a time (one neutral, three 120v hots leads, and a ground,) so it’s a big bundle. Each cable weighs a little over a pound per foot, and there are five bundled together. So a 150’ coil can easily weigh 750-800 pounds.

16 AWG – 1.3 mm^2

14 AWG – 2 mm^2

12 AWG – 3.3 mm^2

10 AWG – 5 mm^2For us from the civilised part of the world ;-)

However, as in Europe we have 230 V system, approximately half the cross section, as stated in the table above, is sufficient.

Both are measurements of cross-sectional AREA and are defined in terms of square millimeters (mm^2), not mm.

That’s exactly what I wrote

mm^2should be rendered to square millimeters (mm^2 ) by the browser / app.

In my understanding, ‘cross section’ always referrs to an area. The other property would be the diameter which is measured in units of length.Sorry, that’s not what I see.

Interesting, what do you see then?

Fwiw, it looks fine using Voyager

Related thing about extension cable reels that many don’t know is that even if you need like 3 meters of cable you should still unspool the entire thing as otherwise it’s acting as a coil and creating resistance. Most cable reels have different ratings marked on them for when they are spooled / unspooled. This is especially true when the device you’re powering takes >1000 watts

Yes! There is a video about this. Heat in spool of cord is trapped.

Many years ago, my mother used the electric lawn mower without unspooling all the wire. When it finally shorted, all the plastic wire insulation was in the process of turning into a melty plastic soup. A Lesson Was Learned.

The reason isn’t resistance - it’s that the coiled wire makes an electromagnet that stores energy in the magnetic field. The alternating current in the mains switches 50 or 60 times a second. In each cycle the magnetic field is created, destroyed then recreated in the opposite direction, then destroyed. This dumps a lot of energy (and therefore heat) into the coil.

The coil wouldn’t make a significant magnetic field because the cable has two wires with opposite current flow in close proximity

But when the cable is coiled, its ability to dissipate heat is less, so normal resistive heating can create higher temperatures

Inductance is not the reason here

I think a lot of people are mostly on the money here. It’s to do with resistance. Now, I’m not a qualified electrician, but I’m an amateur radio license holder and a lot of what you learn for that is applicable here.

The main problem as many have said is resistance. This comes about from both the length of the conductors but also from every plug/socket connection adds resistance. Also in the case of the non extension socket multipliers, as you add more the weight bearing down would also likely start to make the connections less secure causing more resistance and possibly adding to the problem through arcing.

Now the resistance alone on small loads likely wouldn’t be a huge problem. But if you had a large enough load (specifically at the end of the stacked connectors/extensions), or a fault that caused a larger than expected load the current would cause the resistance to generate heat.

There’s a lot of ifs and maybes involved, but really why do it? There’s really no real world situation to need to have a dangerous amount of extensions like this though.

For larger loads here in the UK there’s some very specific other concerns when dealing with ring mains. But really you’d need to do really weird/unusual things for that to become a problem.

On the contrary, practically every single person in this thread that mentions resistance is talking precisely backwards. Higher resistance will not cause overheating. Except for certain motor loads, it will cause malfunction due to voltage drop. The actual fire hazard is the increased chance of faulty cable, faulty connection, and, inevitably, overloading.

Resistance alone doesn’t cause heat. Drawing current through resistance causes heat at the point (or points) of resistance. Which is why I clarified that it’s not likely so much a problem on small loads.

This is why resisters come in different physical sizes. Because they have differing abilities to dissipate power as heat.

A good example is of dummy loads in radio use. Which needs to dissipate the power output of a radio. That can be anything from milliwatts to a kilowatt. Up to probably 50w they will have a basic heatsink. I’ve seen huge drums filled with oil as 50ohm resisters to handle up to a kilowatt of dissipation.

Resistance increases over longer distance cable, and increased load from appliances. (Especially don’t with american electrics, they aren’t fused so the wire can overheat and set fire to the surroundings.)

To clarify a bit, the benefit of the UK system isn’t the end device having a fuse, but the cable itself having a fuse.

In the US the setup would be something like

- Wall has 20A wiring.

- Electrical panel has 20A fuse to avoid the wire in the wall from overheating.

- Extension cord is designed for 10A

- You plug in 2 10A devices to the extension cord.

- The wall wiring is fine, it can take 20A.

- The circuit breaker doesn’t trip as it is also 20A.

- The extension cord overheats and starts a fire.

In the UK the 10A extension cord will have its own 10A fuse in the plug. So when you turn on the two 10A devices the fuse in the extension cord will blow and prevent the extension cord from overheating.

Bold of you to assume that the wall outlet would have a 20a breaker. Most don’t, unless they’re in a kitchen.

But you’re right about the resistance. Also, most extension cords are undersized for the loads they pull, they’re commonly made with 16 or even 18awg wire, further increasing resistance (which translates to heat).

Source: am electrician in US

The circuit power doesn’t matter for the example. I was just picking easy numbers. You can have the same problem as long as the rating of the extension cord is less than the circuit breaker. (And as you pointed that out this is a very common case due to the frequently low rating of extension cords.)

I’m not trying to be ignorant, I’m just curious.

I think you’re in the right community! Don’t let anyone tell you to shy away from asking curious questions. (well, unless the question is also bigoted, illegal, baiting, sealioning, or otherwise disingenuous)

I’m not an electrician in any jurisdiction, but one answer for why two 2-meter (~6 ft) extension cords in series is inadvisable compared to a single 4 meter cord is that it’s not an apples-to-apples comparison. Longer cords necessarily have to be built differently than shorter cords, not only because of electrical codes (eg the NEC in USA) or product safety specs (eg UL, CSA) but also being well-designed for their expected use. There’s also the human aspect, which all good designs must account for as well.

Here in the USA, common extension cord lengths are ~2 m (6 ft), ~7.5 m (25 ft), ~15 m (50 ft), and ~30 m (100 ft). Of those cords, the common wire gauge used might be 18 AWG (~1 mm^2), 14 AWG (~2 mm^2), 16 AWG (~1.5 mm^2), and 12 AWG (~3.5 mm^2). I’ve intentionally rounded the metric units so they’re more analogous to common wire gauges outside the USA. Finally, the insulation used can be anything from “thin, indoor only” to “heavy, abrasion and sunlight resistant”. And while the USA technically has a boat-load of AC connectors, the grand majority will use the standard 2-pin or 3-pin 120v connector, formally known as NEMA 1-15 and NEMA 5-15 respectively. What this means is that chaining extension cords is both possible and somewhat common. The problem is one of mismatched designs.

From a cursory search on the website of a major USA home improvement store, the smallest wire gauge used for a 100 ft cable is 16 AWG. The largest is 10 AWG (nb: smaller numbers mean bigger wire). That thinner cable is marketed for outdoor use. The thicker cable indicates its use “indoor/outdoor” and for heavy-duty applications. It is also branded with a major power-tool company, which would be appropriate as power tools often draw high current.

Whereas looking at 6 ft extension cords, most are 16 AWG but a few were 18 AWG (thinner than 16) or 14 AWG (thicker). But I could not find any thicker cables than that, certainly nothing that uses 10 AWG (~6 mm^2). The “heavy duty” cables of this length also used only 16 AWG wire.

Because electrical resistance is additive in series, and because Ohm’s Law governs the voltage lost at the end of a cord, the use of insufficiently large conductors can cause voltage issues for high-current appliances. Appliances for USA-spec generally require 120 Volts +/- 10%, with utilities aiming to provide 120 Volts +/- 5% from the outlets. This means a “sufficient” power cord should not have a voltage drop of more than 6 volts, give or take. Of course, a high-current appliance will also cause a larger voltage drop than a low-current device, so we only consider the former case.

For a machine that draws 12 Amps attached to a 100 ft extension cord made of 18 AWG wire, the voltage drop would be 15 volts. This is bad for the machine, which now sees a lower voltage than expected. Had the cord been made of 12 AWG wire, the drop is an acceptable 3 volts.

So if you’re operating construction tools, it would be a terrible idea to use three random 6-ft cables, and you should instead use a single 25-ft cable. Even though it’s longer than you need, the fact is that most 25 ft cables use thicker conductors, which reduces the voltage drop overall.

But there’s also that peaky human factor. Sure, there would also be more connectors which could come loose, but the really pressing issue with daisy chained cords is when people do that indoors, because they only have light-duty 6 ft cables handy. And for that Christmas tree, they need to use attach three cables together to go beneath the hallway rug.

This is essentially the worst-case scenario: using thin conductor cords, with thin insulation, underneath very flammable household surfaces, which are also trodden upon by foot traffic. Every step on that cord weakens the insulation and fatigues the conductors. Over time, the conductor becomes thinner where it’s being fatigued, and this increases the voltage drop. An unfortunate result of a voltage drop is that it generates heat. For a cable which is uniformly thin, this heat is spread over the whole length. But for localized conductor damage, the heat is pin-point… directly under a flammable rug.

In the USA, some 3300 house fires started from an extension cord. Because these cords are not within the walls, they are usually beyond the control of often-strict building/electrical codes, something that’s been critiqued by a prominent YouTuber. The US CPSC even goes so far as to create memes to promote their messaging that space heaters – a common, high-current appliance – should not be used with extension cords or strips.

Of course, from an electrical perspective, even a ten-long chain of dinky extension cords would have no problem powering just a single LED night light. But it’s reasonable to ask: 1) is this just asking to be struck down by fate, 2) are there better alternatives like thicker/longer cords, and 3) why isn’t there an outlet where you need it?

(There’s also a scenario where too long or thin of an extension cord can cause a circuit breaker to fail to trip during a short circuit, but it’s fairly esoteric and this post is quite long now)

In short, the blanket recommendation to avoid daisy-chaining cords is to avoid the nasty and sometimes fatal results when that can go wrong, even with it might not always play out that way. There’s almost always something safer than can be done than daisy chaining.

+1 for technology connections video. Was going to post the same link.

The longer the cable, the thicker it needs to be to carry the same amount of current without getting hot. This is due to resistance (Wikipedia does a good job with the details). Basically:

20’ cable be long and thick.

10’ cable be short and thin.

10’ + 10’ cables be long and thin.

Long and thin = heat then fire.

That being said, put an LED light bulb at the end, no problem. Put a gaming PC on the end, problem.

I don’t think you’re right about heat. Two cables in series have double the resistance and therefore double the total heat generation, but that heat energy is split between the two cables so each one does not get hotter than if it was the only cable.

Current and Voltage don’t change, but resistance does (between cable types)?

What are you talking about? Current absolutely changes! Your own formula requires I=V/R

Yes, you will have double heat output due to twice the resistance which causes twice the voltage drop and more or less the same current. But this heat output is spread across twice as much wire, so unless the extension cables are coiled together on the ground each will heat up the same amount as a single one would.

These changes are not linear with extension cords, as the gauge variance is less than changes in length. 100% longer doesn’t mean 100% thicker, and there are material differences in the different lengths, too. Also the heat does not just occur in the wire. Whatever is at the end of that cord has to work harder due to the voltage drop, and harder means hotter.

The smart answer: it can start a fire, don’t do it.

The honest answer: I’ve done it a zillion times and never started a fire. I buy heavy 12 and 10 gauge cords and only chain them to power things that don’t require a lot of amps, like LED lights.

When in doubt, a plug-in power meter is an option you can use to help monitor the situation. Plugs that draw a lot of amps can get warm, even when not using an extension cord. Also, it’s not uncommon for a device to pull a lot of amps on initial power-up, and then settle down to a lower draw.

If you need a ton of outlets, but your total load is under say 200w, is there any harm it? Or in my case, two extension cords separately plugged into a UPS that is plugged into the outlet.

I think it is partly a US specific problem as the quality of the extension cords really suck. Meanwhile in Eurpoe (or at least in Germany) the extension cords actually use the same wire grade as your in wall wires, so there is a basically no difference in using daisy chained extension cords versus different wall outlets (as long as the outlets are in the same curcuit)

Yep, came here to write the same. We have 240V and not 120V like the US. To power the same appliance in the US you have double the Ampere and therefore higher risk of fire (correct me if I’m wrong)

I strongly disagree… We just have higher standards regarding power wires. Since we have more voltage running through the wires we need tougher ones, but that is what regulation is for

So the higher Ampere doesn’t require thicker cables? Genuinely asking. The higher standards and regulations are absolutely part of why you don’t hear this rule here.

Yes, as US uses an voltage of 120 V, the current drawn by a load is approximately double the current drawn by the same load in EU with 230 V. Thus the wires used in Europe only need approximately half the cross section compared to US. However, the insulation of the wires needs to be of higher standard.

Its higher voltage,but yes It does. However the higher standards take care of that, so you don’t have too weak power cables available

Not necessarily exactly the same wires, but all rated for 16A, so the circuit beaker will trip long before any wire gets a chance to heat up

The wires in your wall usually have 1.5 mm^2 while the extension cables have 0.75 mm^2 cross section.

I mean it is hard to find out if they are the exact same, since power strips often don’t specify it, but from handling both I’d say they are pretty much the same…

The cable specification is usually written into or molded onto the outer insulation, at least in Europe / EU.

It’s going to be down to the gauge of the wire and if it’s rated for hard usage. There would be no difference if the 4m cable was the same gauge and insulation type as two 2m cables connected by cord and plug. You couldn’t say how dangerous it is specifically without calculating the load, wire ampacity, ambient temperature, insulation type, distance, and on and on so it’s general advice to prevent fires from overheating wires.

First, I’m not an electrician, or anything even vaguely approaching one.

I’ve never heard that advice with extension cords, only power strips.

You could theoretically link enough extension cords together to cause problems, but it would need to be some extremely shit extension cords or a LOT of them. Resistance increases over distance, which in power cables manifests as them getting hotter. That isn’t a problem until all the sudden it is a problem.

For power strips, the main danger is that you’re potentially introducing more outlets than any of them are rated for. If you’re just using 2 3ft power bars to functionally make a 6ft cable that you’re only plugging a single thing into… you’re fine. Or at least I was, idk I did it for like a whole year. If you’re plugging 16 things into a single wall outlet via power strips you can trip the circuit breaker, or potentially much worse stuff can happen like things getting melty and starting a fire.

If you know enough of what you’re doing to math out the power draw+what your outlet/power strips are rated for you can pretty (afaik) safely daisy chain them if you wanna.

Yeah, there are two components here

- Adding extra length.

- Adding more outlets.

2 is the main problem, but you need a little of 1 to have it fail in an unsafe way (ie. not just tripping the circuit breaker).

If you just add a lot of extra outlets and plug lots of stuff in then you will simply trip the circuit breaker. (Assuming that everything is properly set up according to code.) In order to create a problem you need some extra wiring that is rated for less load than the wall wiring. (Now in practice every splitter has some amount of wiring, so these can be the same device, but most power bars are rated to be “fully used” or have a fuse internally). So the problem looks something like this:

- Have a 20A wall circuit.

- Plug a 10A extension cord into it.

- Plug a power bar or other splitter into the extension cord.

- Put enough devices into the splitter to generate 15A of current.

Now you are overloading the extension cord and risking fire.

Extension cords are rated for certain levels of resistive load based on their length. It typically has to do with the gauge of the wire used in the chord itself. Electrical resistance is typically converted into heat energy. If you daisy chain extension cords and have them plugged into appliances, then the resistive load of the chained cords can be higher than the rating of one or more of the extension cords. This can cause fire.

The longer the cord is the more resistance there is; ie the more electrical load on the circuit. As long as you are pulling less than what the circuit and cord is rated for, there isn’t an issue, you will just be wasting a little extra power from the extra resistance. The plugs themselves can also have a bit of extra resistance.

Two pieces of advice that will make the biggest difference:

-

Keep the total length of all extension cables used as short as is reasonable. Don’t use a 20m cable when a 4m cable will do.

-

Buy extension cords with higher wire gauges (higher wire thicknesses). A 12 gauge cable (4mm2) will provide notably less resistance than a 14 (2.5mm2) or 16 gauge cable (1.5mm2). The packaging will say what gauge it is. Note, I’m talking about the thickness of the metal itself, not the thickness of the extension cord as a whole. I have seen some very, very thick extension cords with absolute trash wires inside.

The more resistance there is, the less the electrical load is. Maximum electrical load would be a short circuit (near zero resistance, maximum current flow); minimum would be a cord or device with infinite resistance (no current flow).

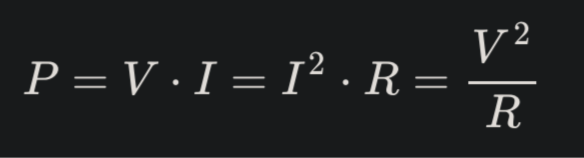

Considering V=I*R and P=I^2 * R, increasing resistance will decrease current and this will decrease power.

-