cross-posted from: https://slrpnk.net/post/7419366

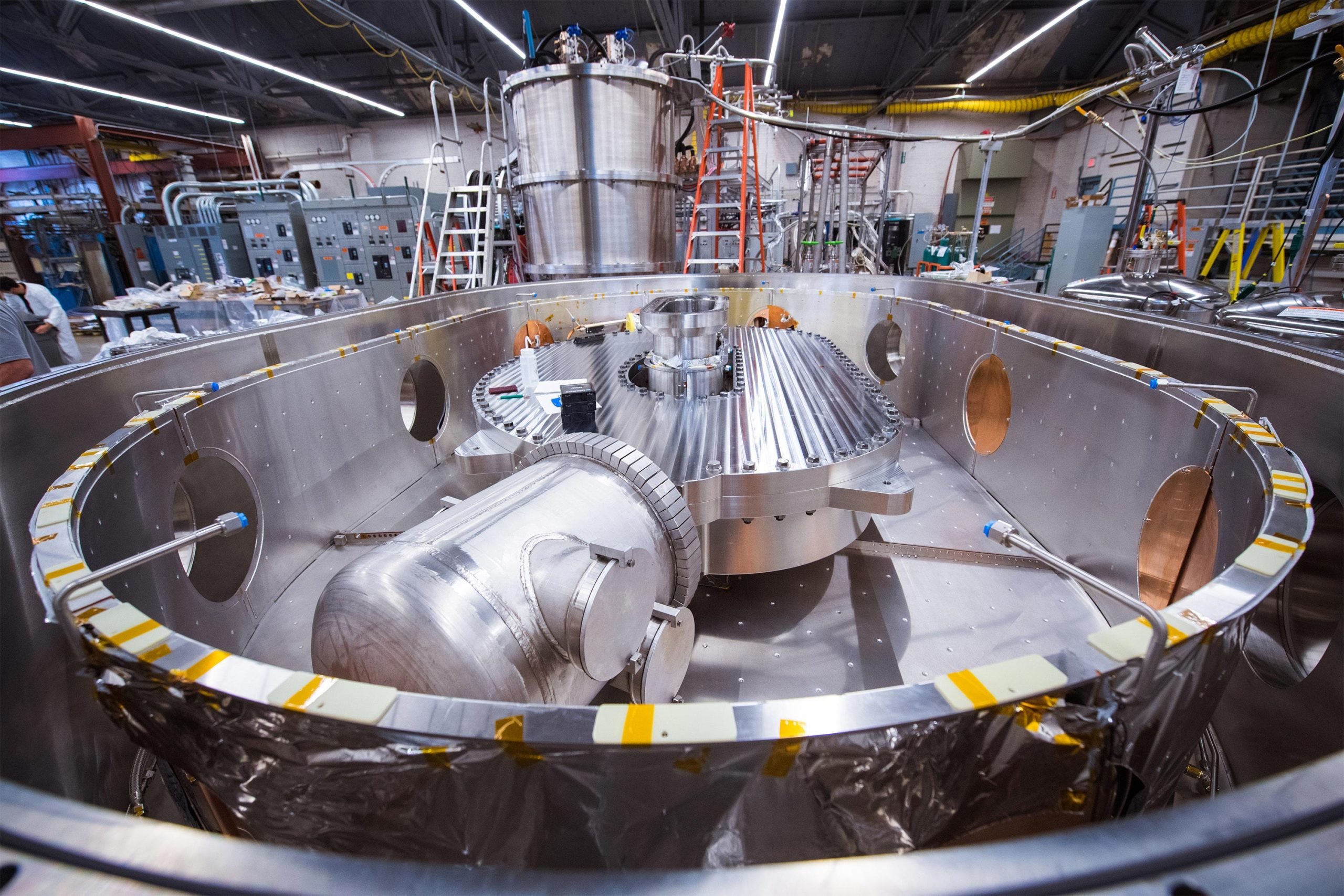

TLDR: New REBCO superconductor can operate with significantly less insulation, allowing them to be built much smaller. Thereby making critical space for other components.

From the article:

“The standard way to build these magnets is you would wind the conductor and you have insulation between the windings, and you need insulation to deal with the high voltages that are generated during off-normal events such as a shutdown.” Eliminating the layers of insulation, he says, “has the advantage of being a low-voltage system. It greatly simplifies the fabrication processes and schedule.” It also leaves more room for other elements, such as more cooling or more structure for strength.

At scale? Or just the one?

Looks like we’ve been making this stuff since 2006 and at decent enough volumes since then.

source