Taiwan Semiconductor Manufacturing Company (TSMC), one of the world’s largest advanced computer chip manufacturers, continues finding its efforts to get its Arizona facility up and running to be more difficult than it anticipated. The chip maker’s 5nm wafer fab was supposed to go online in 2024 but has faced numerous setbacks and now isn’t expected to begin production until 2025. The trouble the semiconductor has been facing boils down to a key difference between Taiwan and the U.S.: workplace culture. A New York Times report highlights the continuing struggle.

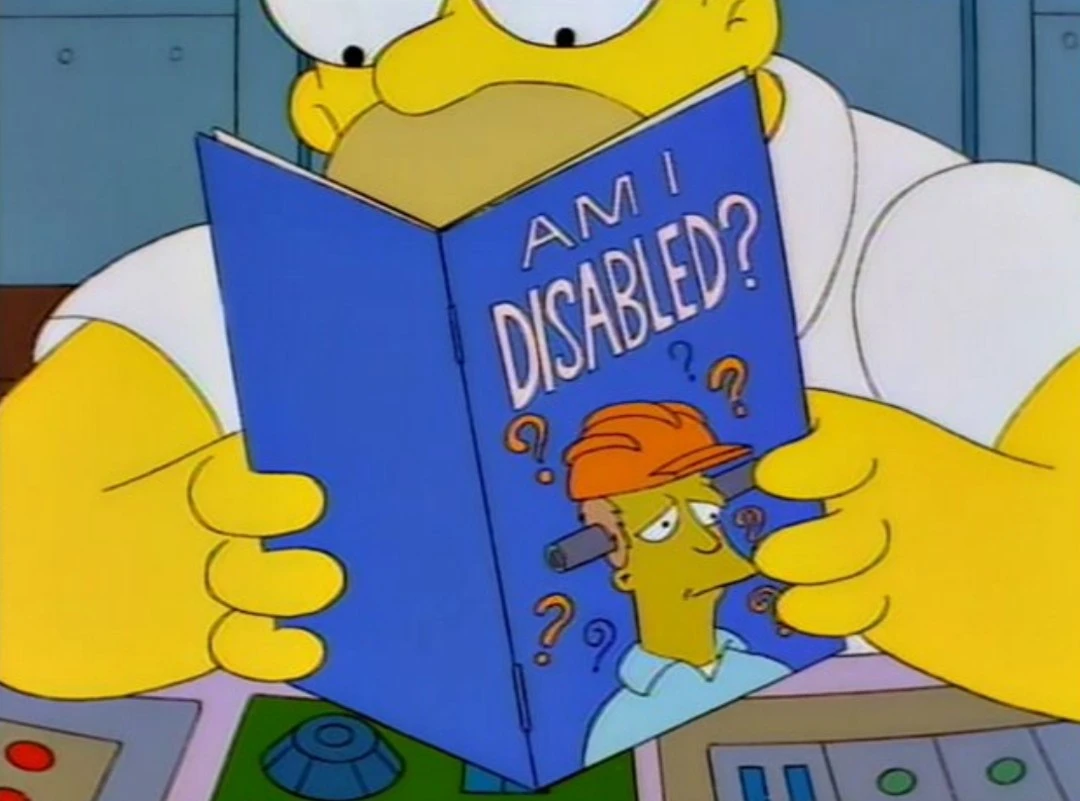

One big problem is that TSMC has been trying to do things the Taiwanese way, even in the U.S. In Taiwan, TSMC is known for extremely rigorous working conditions, including 12-hour work days that extend into the weekends and calling employees into work in the middle of the night for emergencies. TSMC managers in Taiwan are also known to use harsh treatment and threaten workers with being fired for relatively minor failures.

TSMC quickly learned that such practices won’t work in the U.S. Recent reports indicated that the company’s labor force in Arizona is leaving the new plant over these perceived abuses, and TSMC is struggling to fill those vacancies. TSMC is already heavily dependent on employees brought over from Taiwan, with almost half of its current 2,200 employees in Phoenix coming over as Taiwanese transplants.

Beatings will continue until morale improves.

These shiti corps are dealing with demographic shift in US labour force coupled with severe disillusionment since comp barely justifies showing half the time.

Why why would break a sweat to make another man rich lol

People are taking notice.

And AZ struggles to update environmental regs… https://insideclimatenews.org/news/09082024/arizona-copper-mining-water-impact/

“We’re all on wells out here and no one can give us an answer as to what aquifer the water is going to be coming from,” Melissa said of the potential mine in the Galiuro Mountains.

Worrying over water is nothing new in Arizona. Nearly 80 percent of the state lacks any groundwater protections, which has allowed large agricultural operations to move in and pump as much as they want without even keeping track of how much they suck from aquifers or paying a penny for it, leading residential wells in some areas to run dry. Water experts, local leaders and rural residents have pushed for years to change that, with the governor now also calling for action, but legislation to resolve the issue has proven divisive in the state legislature.

Mining operations can also pump as much as they want, even when aquifers are tapped out.

Happy workers are hard workers, treat them like shit and they’ll walk right out the door.

Correct! Well unless, they’re starving and need to feed their families.

It can’t be just that. The cultural difference is real in the sense that there is in Asia in general more obedience or reverence or discipline or selflessness or whatever you call it, that you simply don’t find at scale in western civilisations. Whether it’s good or bad I don’t judge

Well, it’s bad from a western POV.

Funny thing is, TSMC in Taiwan is considered a premium employer. It offers much better pay and parks than other companies.

Parks?

Science park expansion ratified: https://www.taipeitimes.com/News/biz/archives/2023/12/27/2003811196

Perks

Now we don’t know they don’t have kick-ass parks.

You can’t say that, having a park at work is a hell of a perk.

Aren’t the machines TSMC uses made in the Netherlands? They’re the only ones who can get down to that size, and they do it working 36 hours a week…

My brother worked for such a Dutch company (ASM) and often got sent overseas to supervise the setting up of the production lines with these machines.

He mentioned when he’d get sent to Asia, the workers would make sure to get it done over a weekend, while implementing the same setup would take 2 to 3 weeks in the US. In part that was due to the working conditions mentioned, but also simple lack of planning in case of the latter (things would grind down to a haalt because certain changes would need to be made, and the person responsible for the decision wouldn’t respond for hours or days, etc).

Side note: while 36 hour work weeks are common in the Netherlands, 40 hours is still the norm in my experience.

A large chunk of ASMLs workforce is in the US actually.

ETA: about half their workforce is in Europe

Really? Nobody at TSMC thought to google “biggest mistake companies make when opening US plants”? Because this has all happened before

Because this has all happened before

Humans generally don’t consider this.

Specifically East Asian managers, I suppose, think they are the ones who’ll finally do it right and make the serfs grow rice by the schedule and without complaints, and those previous attempts were done by some failures and discards who don’t know how to hammer down nails that go up and so on.

(Not racist, just joking)

I’m reminded of the time Walmart tried to enter Germany with their work culture. But in their case it wasn’t just that the Germans didn’t like it. It was illegal. And the German customers were weirded out by Walmart employees smiling and being so cheerful all the time.

But in their case it wasn’t just that the Germans didn’t like it. It was illegal.

I want to learn more?..

Don’t know if it’s in the video, but as far as I remember it was about how working hours were calculated and about worker surveillance. And Walmart trying to control worker’s private lifes by forbidding sexual relationships between workers.

Also things like selling their loss leaders below purchase price. The kicker is that they still lost the price war they started even though the German discounters kept things legal.

Then there was something about not wanting to publish their balance sheets as they’re required to, shutting out the works council from stuff that the works council has a right to be involved in, the list is endless. Not only did they not have a German CEO to manage all that stuff they apparently didn’t even have German lawyers.

No German lawyers ? The amount of stupidity and arrogance is mind blowing

“What do you mean the rest of the world doesn’t follow US laws?”

And Walmart trying to control worker’s private lifes by forbidding sexual relationships between workers.

Just why would they do that? And were that their concern, wouldn’t such people work better, not worse?

Justification I’ve heard is that if one part of the couple is managing the other, or is promoted after the relationship started, then:

- there is a power imbalance in the couple, possibly one is coercing the other (« I can’t leave him/her, they’ll make my worklife hell / get me fired »);

- there is a risk the manager will promote their partner even if their job performance doesn’t warrant it

Companies will want to both avoid this sort of things, and avoid being seen to enable this sort of things. They might want to move one of the parties to a different department so that the higher up one doesn’t make promotion decisions for the other.

I’ve once worked at a company that wanted to know about relationships between their employees and suppliers/customers’ employees, again because that might enable situations where a supplier / customer is treater favourably because of personal relationships

I guess the rational is that a breakup would lead to worse job performance.

Well, that’s quite strange math, the amount of breakups between Walmart employees is expected to be less that the amount of relationships. Facts from the former are mostly a subset of facts from the latter actually.

Unless we consider the possibility that couples come to work at Walmart and break up there, but couples rarely form while already there.

By law: 8 hours as the rule, never more than 10 hours for exceptions.

By contract, they can go a little above the 8 hours.

If they go above the 10, it can cost the company a lot even for a single case.

So they didn’t plan even for such simple things. Wow.

Apple still tries to have the cherry up-beat customer services department in the UK and it doesn’t work. It’s a Saturday, no one wants to be doing this call, don’t pretend otherwise it’s weird.

Reminds me of the Netflix show “American Factory” about a Chinese factory opening in the US.

Quite a fascinating clash of cultures.

Which reminded me of an 80s movie called Gung Ho about a Japanese company that bought an American automobile manufacturer and the ensuing culture clash.

All this has happened before, and all this will happen again.

So say we all.

I remember watching a documentary a few years ago where this exact situation happened. Chinese company buys American company, tries to establish their work culture and it just doesn’t work.

It’s the same the world over. I’ve worked for years for a western company which has got a large part of their business in Asia and China.

You try taking our “western ways” of leadership to China and see how well it fares; what I would consider “leaving space for a leader to operate and feel accountable” is seen as “my leader has no fucking clue what he is doing; he never tells me what he wants me to do”.

Culture eats everything for breakfast. As a western leader in China you have to act like a controlling maniac (in my cultural frame) to be seen as an effective leader in China.

And it goes both ways. My brother reports to a Chinese manager transplanted to the west and she “desperately wants to micromanage everything” according to the western team.

We are all trying our best.

Probably American Factory from 2019. Definitely a recommended watch for anyone unfamiliar with the topic.

Went back to see the trailer and yeah, that’s the one.

Yep that’s probably the one. Super depressing, especially all the anti-union tactics.

Oh, I think I saw this movie https://en.wikipedia.org/wiki/Gung_Ho_(film)

I hope they can be held accountable for mistreating those 'transplants" (what an ugly word!) too. But I guess that would be easier here in EU than in USA.

So what happens to Taiwanese manufacturing when their population collapses due to a super low birthrate. They right behind South Korea in lowest TFR.

It’s happening all over the place. They’re either going to have to lean heavily into automation (where possible), and/or accept mass immigration from parts of the world that continue to have a high birth rate – although as we’re seeing in a lot of places, that can be a tough sell politically.

accept mass immigration from parts of the world that continue to have a high birth rate

Would that not likely result in similar, but different, friction between cultural expectations about working conditions etc?

To my thinking you’d still have the problem TMSC is having right now, just more widespread as they have to adapt to whatever the culture being imported everywhere to shore up worker counts is everywhere it is happening.

W for workers rights, L for US fab production

It doesn’t mean that the US factory is any less capable. What needs reworking is meeting the expectation and planning for contingencies. There should be ongoing shifts, specialized teams, rotation, mitigation, etc. I think our output is comparable but it’s done more safely and sustainable over a longer time VS grinding workers to dust and replacing them.

It’s not about capabilities, it’s about cost.

If you can exploit your workers, pay shit wages for long hours, you’ll get a cheaper product. You can get the same output by applying higher standards, but that would mean hiring more people.

The more time i spend in manufacturing environments ( I spend all my time there) the less i see actual product being the finished good. Business are setting themselves up for this autopilot pipe dream of “AI gonna fix everything” marketing/engineering utopia and in reality all it’s doing is dividing your operations crew and management. They are neglecting equipment, default mode of compliance is non compliance because of awful processes and quality cutbacks (staffing staffing staffing) and at the end you get a product that’s probably not gmp but who cares it’s shipping.

That’s the nature of capitalism.

Look at healthcare, software, construction. Unless there’s a very clear incentive to produce high quality (laws or enforceable contracts) things will go lower and lower in quality.

And unfortunately, a lot of consumers don’t care all that much about quality. They want crap that looks fancy.

It’s the nature of both market economies and planned economies. Strong unions are needed in both.

This last job (I’m a contract employee) will be my last in MFG. I was hired long term (2 years) to get a gsk/haleon site to add almost 40% more deliverables. 280 million units a year to 400 million. Reduce waste by 25%, CoA/CoE turn around down to 2 weeks from 6.

The labs, which operate almost entirely as a community (eg no real rigid structure, lots of senior empires) killed it. 7 day turn around which honestly now my mind. Packaging was a struggle once i pointed out that OEE can be improved by scheduling downtime rather than just oopsing it (strictly beancounter bullshit).

Manufacturing… Took my ideas, literally threw them in the trash in front of me and said they have experts from multiple countries, they don’t need my help. Cool, i still get paid so whatever. You wanna see the biggest dumpster fire ever… Laid off about 40% of the mfg work force, rolled out some bullshit trainings about operators and maintenance working to bring equipment “back to new” whatever the duck that means (means maintenance budget is gone) all while investing 0 dollars into repair and maintenance. Gear boxes leaking oil into overflowing catch cans for months. Vacuum traps actually pulling ingredients out of the batches, building more systems upon systems that they can’t validate. Cleans that won’t pass swabs, cleans that aren’t validated, processes that rely 100% on operators to transcribe SCADA data into an electronic batch record system.

Never seen anything like it but i know when a horse is dead and this one was dead before i got there.

As a software engineer, this is exactly how software works.

Everything is just a huge mess bolted and duct taped together, sometimes over decades. And it’s all way too complex to understand and crap like crowdstrike happens.

You can’t rely on anything anymore and I’m pretty sure, our highly interdependent world will come very close to collapse if anything major happens. Covid was a warning shot, but nobody heard it.

I don’t think there will be a collapse just because there is no meticulous maintenance or development. Most likely, in the future there will just be an accident or tragedy that will improve standards and safety.

If you want a collapse you have to pray that all the factors attack at the same time, because if only one does the attack they only strengthen humanity see Late Bronze Age collapse.

Look at crowdstrike. A tiny error disabled millions of computers for hours. Think about what would have happened, if this wouldn’t have been an error, but an actual attack.

Look at the supply chains of medical supplies. One major outbreak of some bacterial disease in India or China will lead to them stopping exports and since so many pills are produced there, a huge drop in global supply.

Look at the undersea cables. There are not that many and capable malicious actor could easily destroy a lot of them.

Look at the power grid. I don’t know about other parts of the world, but the European grid, spanning pretty much all countries in Europe plus turkey, has no plan for a cold start. If it breaks down, there’s gonna be blackouts for weeks.

Of course, none of that will end society, but that’s not how collapses work anyway. One event triggers another, and the combination leads to the collapse itself.

The CHIPS Act is going well.

Sounds like they need a union

perceived abuses

Way to be passive aggressive, haha. Next they’ll be apologising “we’re sorry you feel that way” :P